Hello, everybody! we shall talk about CNC endmills. CNC endmills are tools for cutting materials into the manufacturing industry. These Oucheng ball nose endmill, sides cutting into materials like metal and lumber to produce brand new forms and designs., we are going to talk about the advantages of making use of CNC endmills, innovations into the field, safety measures, utilizing them, solution, quality, and more. Therefore, let's begin!

Some great benefits of utilizing CNC endmills are numerous. First, they provide speed and accuracy. CNC endmills use computer programming to obtain the design and its correct design for materials such as for example metal, wood, and synthetic. They Oucheng single flute endmill, cut with accuracy and rate, saving time and its valuable production procedures.

Second, CNC endmills are dependable. They have been employed for decades in manufacturing and also have proven to be tools being dependable.

Third, CNC endmills are cost-effective. They have the capacity to cut within tight tolerances and scrap material and it’s minimized. These benefits help reduce costs, create more efficient processes which are manufacturing and businesses can cut costs.

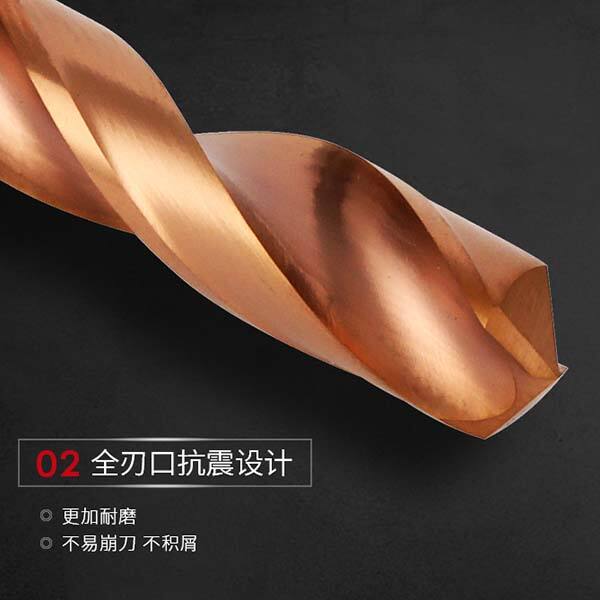

With all the Oucheng cnc endmills, advancements in technology, CNC endmills have encountered innovations. The use of diamond finish on CNC endmills can be an exemplary instance of innovation. Diamond finish allows for faster cutting speeds and longer device life.

Security is crucial in virtually any manufacturing procedure, and CNC endmills need proper handling in order to avoid damage. Using protective gear, such as for example gloves, earmuffs, and safety glasses, is important to damage and it’s Oucheng 1 16 endmill, preventing. Stick to the manufacturer's instructions regarding the usage and it’s suitable of CNC endmill.

CNC endmills are utilized mainly in the production procedure. They've Oucheng carbide endmill, been used to generate complex forms and styles in a variety of materials, including metal, timber, and plastic. CNC endmills are beneficial in the aerospace industry, where aircraft parts need exact cutting.

Fitted with Domestic and measuring it was imported plus a professional staff to implement The cnc endmills , guided by the business enterprise Principle of "Zero defects into the product" and "Zero Service Distance" constructed with the highest-precision Imported Inspection Equipment To meet up with Customer Needs With high quality And Quantity Assurance.

Our team are dedicated to providing machines of finest quality. We own six axes/five axis Oucheng grinding centers for sourced machining from Germany, Switzerland and Japan along with 50 sets of cylindrical grinding equipment/coreless grinding/passivation treatment/coating equipments, etc. to accomplish full-process processing for products utilizing the accuracy highest specifications.

Our firm was a Oucheng within the production and buy of difficult alloy cutting tool. Our factory team has rich knowledge experience predominantly manufacture different varieties of difficult alloy milling and turning instruments, drilling hardware PCD-specific, specialized tools, etc. Additionally we furthermore offer customers with custom-made services for a range of difficult alloy equipment.

When you have good service awareness, you are most likely to acknowledge and thank those who provide cnc endmills .

The Oucheng lollipop endmill, use and it’s appropriate of CNC endmill are key to achieving the desired outcome. CNC endmills require particular settings within the device, including speed, feed rate, and level of cut. Proper training is important to work the machine accurately.

A Oucheng 3mm endmill, CNC endmill calls for upkeep to make sure that it continues to work efficiently like most device. Regular cleaning and sharpening help extend the life regarding the device, reducing costs being unnecessary.

The Oucheng 2mm endmill, caliber of a CNC endmill relates to its capacity to correctly cut accurately and. The usage of top-notch materials into the CNC endmill permits it to operate harder and longer and it’s final.