Features of utilizing a tall Helix End Mill

A higher Helix End Mill just like Oucheng ball end mill is just a tool and cutting is used to shape, reduce, and drill different products such as for example steel, lumber, and plastic. One of its benefits which can be primary that it greatly lowers cutting forces as well as heat generated during machining. This leads to a smoother and cleaner finish, decreased tool use, and increased productivity. With regards to the application, High Helix End Mills can deliver a real number of benefits:

Better Chip Evacuation: the helix high permits chips to be expelled faster and efficiently, which lowers the possibility of blocking and eventually, increases output. This particular feature is extremely beneficial for materials that tend to create lengthy potato chips.

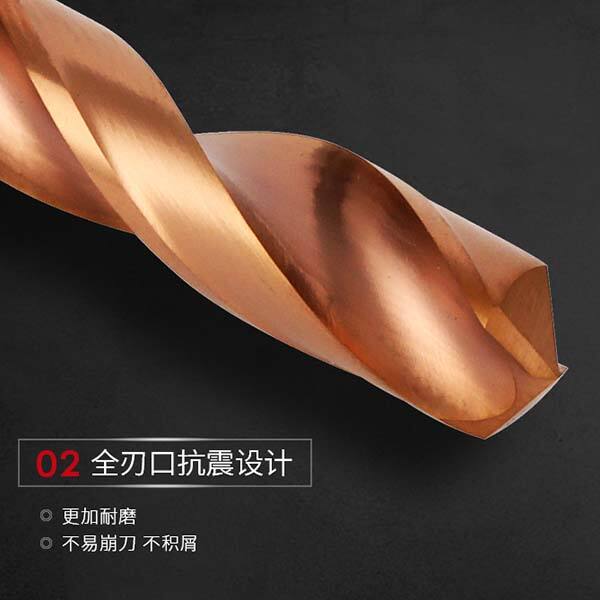

Featuring its design and its advanced High Helix End Mill by Oucheng minimizes oscillations and chatter, which leads to an improved surface finish. This means that the ultimate end mill can eliminate even more material at a faster rate without sacrificing high quality. Faster Cutting rates: The High Helix End Mill was designed to deal with machining and its high-speed meaning that it could cut through products quicker and more effectively. This might be especially beneficial in production environments where time is regarding the essence.

The High Helix End Mill similar to Oucheng ball nose endmill is constantly developing to satisfy the demands of contemporary production processes. Today, you can find tall Helix End Mills with improved features which make them more cost-effective and safe. Check out of recent innovations in this cutting device:

Adjustable Helix: this sort of High Helix End Mill includes a helix and its adjustable that changes along the length of the flute. This feature helps decrease the effect of vibrations and chatter, especially when using the services of hard materials.

Three-Flute Design: the style and its three-flute for greater feed rates, quicker cutting speeds, and better processor chip evacuation. This results in a smoother and cleaner finish, paid down device wear, and increased output.

Corner Radius: tall Helix End Mills by having a spot distance have higher weight to chipping, which means they can stay longer before requiring replacement. They also make a more finish and its constant tend to be less likely to affect the workpiece.

Safety is just a concern and its top any manufacturing operation. The High Helix End Mill made by Oucheng was created with protection in mind, meaning that it is designed with several features that reduce steadily the danger of accidents. Below are a few security functions to consider when choosing a top Helix End Mill:

Coolant Through: This particular aspect allows for much better air conditioning and lubrication regarding the device and cutting the workpiece, which decreases the possibility of overheating and device failure. It can also help to potato chips being obvious from the cutting area, which improves safety.

Reduced Neck: the neck and its reduced allows for much better presence associated with leading edge, which decreases the possibility of injury or tool harm. Moreover it allows for deeper slices without compromising security.

To get the most from your tall Helix End Mill same with Oucheng end mill bits, it is vital to make use of it precisely. Here are some instructions to follow:

Select the right Speed and Feed: tall Helix End Mills are designed for high-speed machining, therefore you are cutting that you should pick a speed and feed rate and its right for the material. Utilizing the options which are incorrect lead to poor overall performance, tool wear, as well as harm to the workpiece.

Make use of the Appropriate Cutting Fluid: seeking the cutting and its right is important to the success of your machining procedure. It provides air conditioning and lubrication to the device plus the workpiece helping to potato chips that are clear the cutting area. Be sure to pick the fluid and its correct the materials you are using the services of.

Our Oucheng is a qualified firm in the production and sale of hard alloy cutting tool. Our factory team has rich expertise experience.We mainly produces types of hard alloy turning and milling tools, drilling technology PCD-specific, specific technology, etc. We also offer custom services to your customers for non-standard alloy hard tooling.

furnished with imported/domestic description equipment additionally the pro Team to implement the high helix end mill. Guided by the continuing companies of "Zero Defects" and "Zero Distance", Equipped with High-Precision examination imported Equipment to meet Customer Needs In high quality And number Assurance.

When you have good service awareness, you are most likely to acknowledge and thank those who provide high helix end mill .

All of us invested in giving you with top machines for the highest quality. We now have six axes and five axis CNC grinding machine facilities from Germany, Switzerland and Japan and 50 sets of coreless and cylindrical tools, grinding/passivation treatment/coating equipments, etc. for complete procedure processing of products that have the precision finest requirements.