The Magic of Down Cut End Mill

Introduction:

Down cut end mill, perhaps you have ever heard of it? It is a magical tool which will help you to produce amazing and precise cuts on various materials including wood, plastic as well as metals. Let us look at the advantages, innovation, and safety features of this awesome device and find out how we can get the most out of it. Apart from that Oucheng product does precision manufacturing known as down cut end mill.

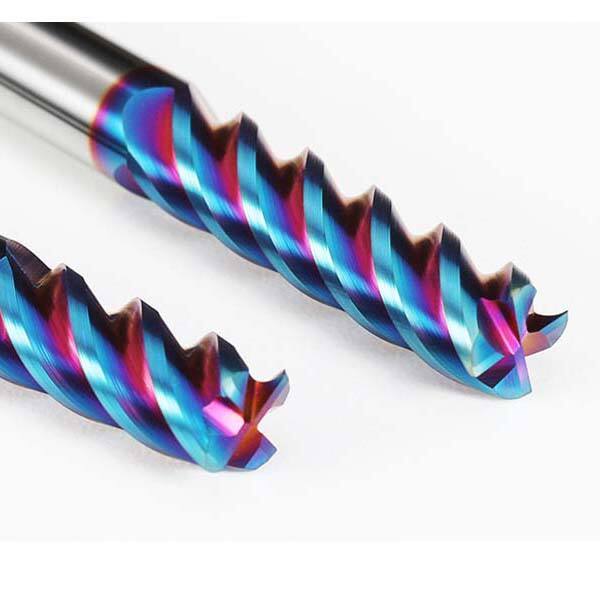

The unique design of down cut end mill makes it superior to other milling tools in several ways. Also select Oucheng product for unrivaled dependability and performance such as end mill cutter. It cuts downwards thereby reducing the risk of material chipping, splintering or tearing especially on brittle or delicate materials.

The down cut end mill is an example prime of in neuro-scientific milling. Its design is based on standard up cut end mill, which cuts upwards and leaves a rougher finish. Furthermore, unlock new levels of efficiency with Oucheng product, including cutter end mill

The down cut end mill calls for caution and proper control to avoid accidents or accidents like all power tools. Always stick to manufacturer's instructions and use safety acceptable, such as attention protection, gloves, and a face shield. Besides that, discover why Oucheng product is top choice of professionals, for example milling end mill cutter.

The down cut end mill would work for a wide range of applications and materials, with respect to form specific size, and coating associated with device. It can be used for contouring, profiling, slotting, and drilling, among other operations. Moreover, experience unrivaled performance of Oucheng product, known as, carbide end mill cutter.

It is paying attention in down cut end mill with effort place in to produce your experience pleasant, be it at a restaurant, store, or any other service provider.

Our Oucheng is an ongoing expert company are engaged to the development manufacturing, production, and distribution of cutting tools produced from hard alloy. Our team consists of professionals insurance firms a wide range of. Our main products cutting, switching, and drilling gear. In addition we offer customers with customized services for a true number of non-standard alloy hard equipment.

All of us is specialized in providing you the high quality highest machines. We want Five Axis and Six Axis CNC Grinding Machining Center Equipment from Germany, Switzerland, Japan, China, As Well as 50 sets of cylindrical grinding/machines passivation grinding/Coreless Etc., To Perform Full procedure Processing For products with high precision Needs from Customers.

Fixed with Domestic and brought measuring in and expert personnel in order to make usage of the down cut end mill high quality guided program by the organization philosophy of "Zero defect in product" and "Zero Service Distance" sustained by High-Quality Imported Inspection Equipment to generally Meet subscribers' Needs with Quality and Quantity Assurance.